Happening Now

Are US crashworthiness standards “dooming” passenger rail?

June 18, 2013

Written By Colin Leach

One frequent criticism of passenger rail’s viability is that it entails high fixed costs and thus discourages potential investors. While many of these costs, such as track maintenance and equipment maintenance, are relatively constant, at least one can, according to a recent study, be significantly lowered: that of equipment purchases.

In a new paper released by the Competitive Enterprise Institute, David Edmonson argues that outdated Federal Railroad Administration (FRA) safety rules prevent passenger rail operators from purchasing standard European and Japanese equipment, and as such must spend significantly more to buy FRA-approved equipment. This “heavy burden”, Edmonson maintains, has no basis in modern safety standards and places operators at a “disadvantage in the transportation market without any appreciable gain in surface or safety.”

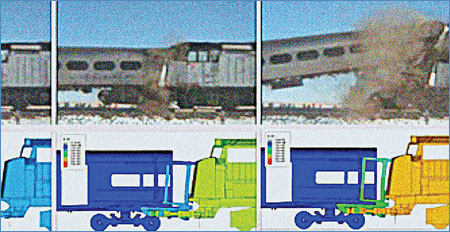

Edmonson’s argument centers around the question of “buff strength” requirements, which mandate that a railcar’s undercarriage be able to resist a certain amount of force before enduring permanent damage. Upped to 800,000 lbs from the initial 400,000 in 1945, buff strength requirements have been imposed on all new intercity and commuter rail equipment since 1999. Such an approach, Edmonson observes, contradicts that adopted by European regulators. Rather than requiring such a high “buff strength”, European authorities instead mandate that all cars utilize a technology known as “crash energy management”. Crash energy management calls for crumple zones to be located in non-passenger areas such as electrical closets and vestibules; these zones absorb a crash’s energy and thus lower the need for a high buff strength.

The effects of a higher buff strength, Edmonson contends, are higher maintenance costs and underperforming equipment. Although no American companies presently make electric and diesel multiple units (EMUs and DMUs), any company that tried would find itself unable to export their units due to their incompatibility with the more dominant European safety standard. To avoid these pitfalls, the author recommends that the FRA revise its rules and adopt European standards- or, alternatively, simply grant more exceptions to allow equipment not compliant with the current US standard.

But Edmonson’s approach has both pros and cons. While relaxing FRA standards would certainly permit acquisition of less expensive equipment and allow operators to purchase equipment with proven reliability records, the practicality of doing so is questionable. While the author acknowledges that the comparatively heavier weights of American freight locomotives and cars have been cited as justification for the FRA’s purportedly excessive standards, he dismisses buff strength as an irrelevant requirement. He maintains that this is particularly true for passenger operators that do not have to share their tracks with heavier freight trains, as is supposedly the case with the Long Island Rail Road.

However, as the LIRR actually shares tracks with freight service, the FRA’s caution is not entirely misplaced. Furthermore, as demonstrated by the crash on Metro-North in Connecticut, higher crush requirements can save lives. Senator Richard Blumenthal (D-CT) noted that the Kawasaki M8 EMU’s reinforced design was “surprisingly” crashworthy and likely prevented deaths.

A relaxation of FRA's crashworthiness standards should be pursued in conjunction with the legally-mandated installation of Positive Train Control (PTC) systems on all passenger-carrying lines in the US. PTC, by preventing collisions in the first place, can make it possible to use lighter passenger train equipment with an even greater degree of safety than currently exists in this country.

"The COVID Pandemic has been and continues to be the biggest challenge faced by Americans as it has taken a deadly toll on the world and on the world’s economies. During COVID Locomotive Engineers at Amtrak and other Passenger and Freight Railroads have embodied the definition of essential workers. This dedication by our members is not new. We applaud the Rail Passenger’s Association for recognizing the vital contributions of our members and their hard work moving Americans and freight during the COVID pandemic."

Dennis Pierce, Brotherhood of Locomotive Engineers and Trainmen (BLET) National President

December 21, 2021, on the Association awarding its 2021 Golden Spike Award to the Frontline Amtrak Employees.

Comments